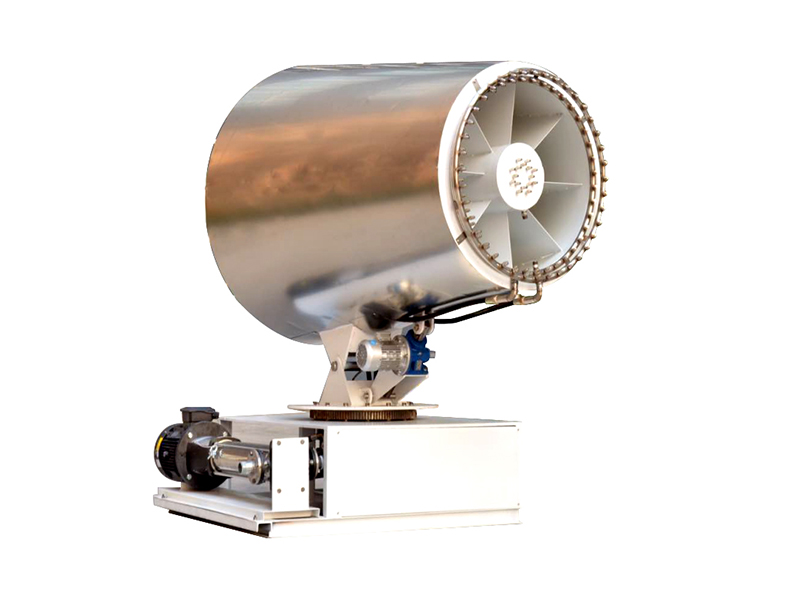

12 m³ Snow Melting Agent Spreader QX-SBJ12000

Model:QX-SBJ12000

Length × Width × Height (mm): 6000×2200×2300

Conveying Method: Chain Conveying

Spreading Rate (Adjustable) (g/m²): 20~200

Spreading Width (m): 3~16

Operating Speed (km/h): 10~45

Performance Features

12 m³ Snow Melting Agent Spreader QX-SBJ12000

The snow melting agent spreader is suitable for snow and ice melting operations at airports, docks, highways, provincial roads, national highways, large factory compounds and squares.

1. Wide Application: Capable of spreading coarse salt, fine salt, deicing agents, dry sand, special snow melting agents, etc.

2. Superior Corrosion Resistance: The whole machine is treated with steel plate painting and three-level anti-corrosion process, ensuring long service life and corrosion resistance.

3. Reinforced Material: The spreading disk is made of high-quality stainless steel with excellent corrosion resistance.

4. Wide Vehicle Compatibility: For chassis of different vehicle models, the lifting adjustment range of the spreading disk is 0~350mm to ensure the ground clearance.

5. Uniform Spreading: Both spreading rate and spreading width are adjustable.

6. Convenient Storage: The spreading disk can be flipped and folded for easy unloading and storage.

7. Deflection Mechanism: Equipped with a spreading deflection structure, it can realize asymmetric spreading to the left or right to adapt to different road conditions.

8. Unloading Function: Built-in unloading function prevents material caking in the hopper.

9. Easy Loading & Unloading: The whole machine adopts a detachable dedicated lifting support system for convenient storage in non-operating state.

10. Waterproof & Moistureproof: The tarpaulin above the hopper isolates rain and snow to prevent snow melting agent particles from getting damp and caking. The tarpaulin material has good flexibility and durability.

11. Easy Maintenance: The detachable and adjustable spreading disk mechanism facilitates installation and cleaning.

12. Uniform Feeding: The spreader is equipped with a filter screen to reduce large particles or impurities from entering the equipment, ensuring the safety of the equipment, pedestrians and vehicles.

13. Rational Structure: A specially designed pressure relief device inside the hopper protects the normal operation of the equipment. The hopper adopts a V-shaped structure, which is simple and reliable, enabling automatic blanking of snow melting agents with complete discharge and no residue.

14. Powerful Power: Fully hydraulically driven with stable performance and reliable quality. It adopts self-contained engine power and hydraulic transmission, with scraper chain structure for forced conveying, ensuring uniform and reliable discharge and easy maintenance.

15. Lighting & Warning: Lighting and warning lights can improve driving safety in severe rain and snow weather, and facilitate operators to observe the working condition of the equipment in a timely manner.

16. Easy Operation: Startup, shutdown and spreading are all controlled in the driver’s cab, making the equipment operation convenient and safe.

Technical Specifications

Model: QX-SBJ12000 Snow Melting Agent Spreader

Hopper Volume (m³): 12 m³

Length × Width × Height (mm): 6000×2200×2300

Conveying Method: Chain Conveying

Spreading Rate (Adjustable) (g/㎡): 20~200

Spreading Width (m): 3~16

Operating Speed (km/h): 10~45

Hydraulic System Working Pressure: ≥16 MPa

Hydraulic Flow Rate: 40 (L/min)

Motor Displacement: 420 (ml/r)

Salt Spreading Rate (g/m²): 20~200 Adjustable

Working Speed (km/h): 15~60 Adjustable

Spreading Disk Diameter (mm): 500

Spreader Lifting Mechanism: Adjustment Height 0-500mm

Control Unit: CBN10

Power Source: Hydraulic Motor Drive

Single-cylinder 195F Air-cooled Diesel Engine: 9.2 KW, Voltage 12V

Accessories: Top Rain Cover, Ladder, Lighting Lamps

Working Principle

The hydraulic pump drives the motor to rotate, conveying the snow melting agent in the hopper to the spreading disk. The motor drives the high-speed rotating spreading disk to evenly spread the snow melting agent.

Performance Advantages

Equipped with a single-cylinder 195F air-cooled diesel engine, it is environmentally friendly, energy-saving and highly efficient. With a built-in preheating function that requires no separate operation, the diesel engine is heated in winter to facilitate the startup and operation of the equipment in cold weather.

Installation & Fixation Method

Snow Melting Agent Spreader Operation & Maintenance Manual

Thank you for choosing the snow melting agent spreader produced by our company. This product is equipped with a stable and reliable hydraulic conveying and spreading system. Operators must understand the main functions and structure of the equipment and receive training before operation. During operation, pay attention to warning signs to avoid equipment damage caused by misoperation and unnecessary losses.

Loading and Fixation Method of Snow Melting Agent Spreader

As winter approaches, road snow removal and traffic guarantee work are put on the agenda. The spreader can be loaded onto vehicles by using a crane or other lifting equipment. The spreader and the vehicle body must be securely connected before carrying out snow removal operations on roads.

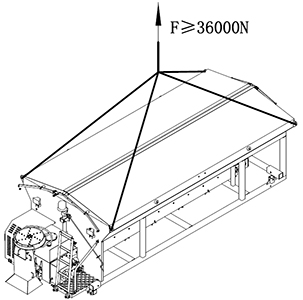

1. Loading

The equipment can be loaded onto corresponding vehicles or horizontal ground by lifting the four lifting lugs of the spreader, as shown in the figure below.

Note: The maximum lifting capacity of the lifting equipment and slings shall be ≥ 3.6t.

Note: Empty the snow melting agent in the hopper before lifting; lifting with load is strictly prohibited!

Lifting operations involve safety risks and must be performed by professional personnel!

2. Vehicle Body Connection

1) After loading the spreader onto the vehicle, connect and tension the spreader to the carriage body by using hooks + rigging turnbuckles + lifting chains, as shown in the figure below.

2) Install and lock the left and right positioning pins to prevent the spreader from moving forward during driving, as shown in the figure below.

Note: Before each operation, inspect the integrity and reliability of the connecting rigging to ensure it is tight without loosening. Replace any deformed or cracked components in a timely manner.

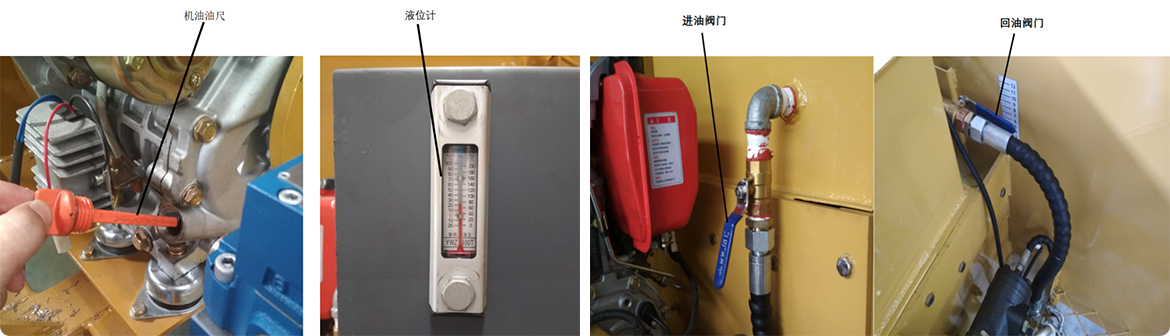

Pre-operation Inspection

1. Check whether the connection between the snow melting agent spreader and the vehicle body is firm and reliable, and whether the rigging is in good condition;

2. Check whether the engine oil level (left figure below) and diesel fuel level meet the working requirements.

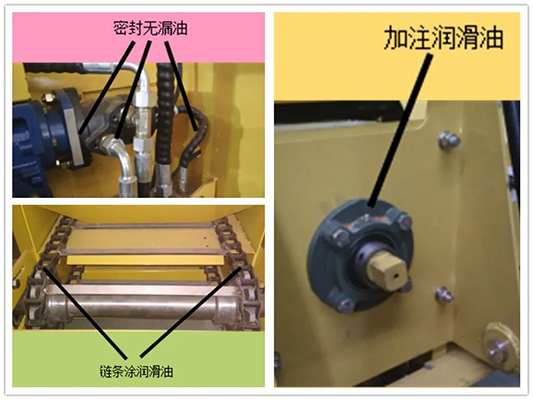

3. Check whether the hydraulic oil tank level is above 2/3 of the liquid level gauge (right figure above), whether the inlet and return oil circuit valves are open (figure below), and whether the hydraulic pipeline connections are sealed without oil leakage.

4. Check whether the reducer is filled with worm gear lubricating oil, and whether all lubrication points and sliding surfaces are filled with lubricating oil and grease.

5. Check whether the battery power is sufficient.

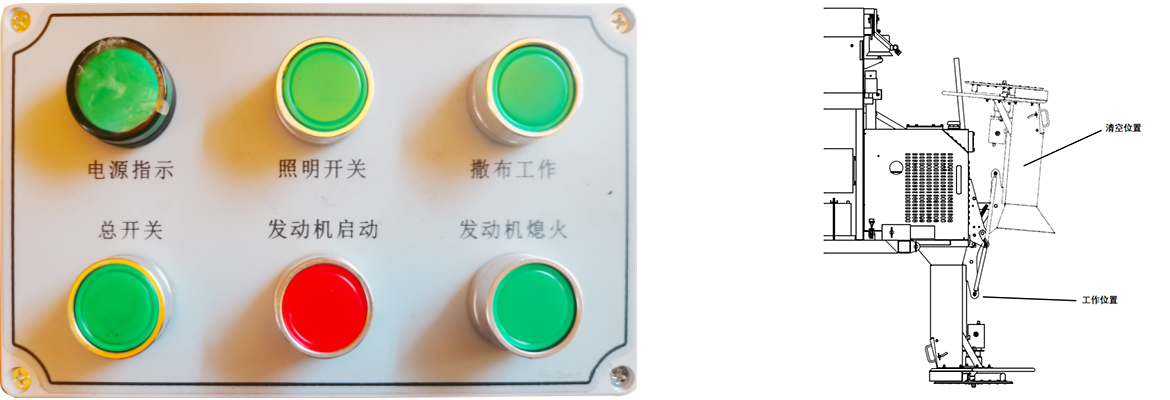

6. Ensure that all switches and buttons of the control box (figure below) are reset, the overflow valve is opened and closed normally, and the warning lights and lighting lamps are working properly.

7. During operation, rotate the blanking and spreading system to the working position and lock it; when tilting residual materials, place the spreading disk in the emptying position and fix it (figure below).

8. Check whether the scraper chain runs normally. Before the snow removal season, conduct no-load test operation for 10-15 minutes to check for jamming. If jamming occurs, add grease to the bearing positions and apply grease to the scraper chain before loading materials for spreading work.

简体中文

简体中文