10 m³ Snow Melting Agent Spreader QX10LF/SBJ

Model:QX10LF/SBJ

Volume (m³): 10

Tank Rust Prevention: AB3DH5 Anti-rust Treatment

Weight (kg): 2500

Main Engine Power (hp): 24

Solenoid Valve: Imported CCT5A-30 Solenoid Valve

Technical Specifications

10 m³ Snow Melting Agent Spreader Model: QX10LF/SBJ

1. Overall Dimensions (mm): 5650×1900×2300

2. Volume (m³): 10

3. Tank Rust Prevention: AB3DH5 Anti-rust Treatment

4. Weight (kg): 2500

5. Main Engine Power (hp): 24

6. Solenoid Valve: Imported CCT5A-30 Solenoid Valve

7. Hydraulic Pump: CBW-F316

8. Conveyor Belt Hydraulic Motor: BM2-400

9. Spreader Disk Hydraulic Motor: CMED-F310

10. Snow Melting Agent Conveying Method: Screw Conveyor

11. Spreading Width (m): 3~15

12. Salt Spreading Rate (g/m²): ≥150

13. Working Speed (km/h): ≥10

14. Spreader Disk Diameter (mm): 400

15. Spreader Lifting Mechanism Adjustment Range (mm): 500

16. Spreading Angle (°): 45° Left and Right

17. Engine: R2v Air-cooled Diesel Engine

18. Transmission Method: Belt Conveyor

19. Filter Screen Specification (mm): 20 Mesh × 0.850

20. Accessories: Supporting Legs

Product Actual Photos

Configuration Description

1. The hopper is made of Q345 steel plate, suitable for loading snow melting agents and their mixtures; equipped with a screen on the top.

2. The hopper is treated with anti-corrosion technology, and the spreading device is made of stainless steel, providing excellent anti-corrosion performance for the whole machine.

3. Independent power source and hydraulic transmission ensure high transmission efficiency, stable and reliable performance.

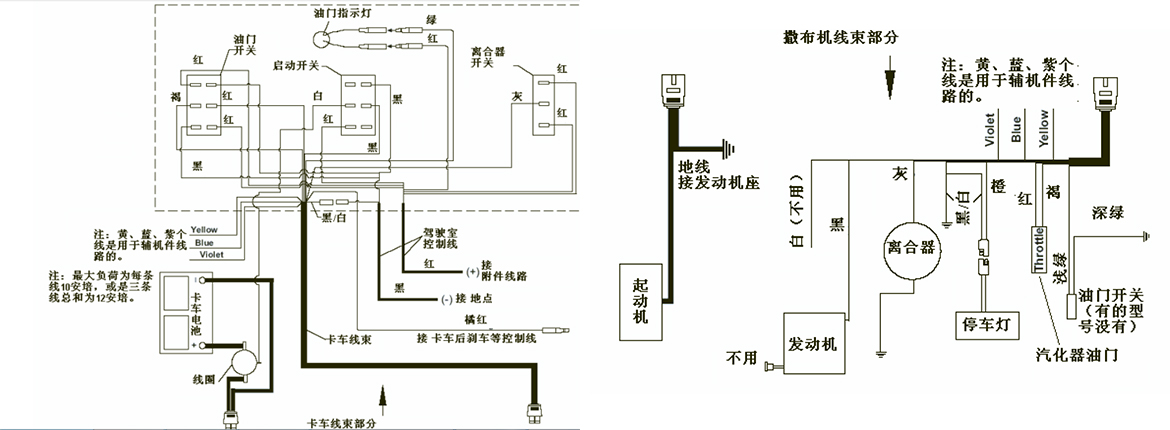

4. The solenoid valve control circuit is connected to the driver’s cab for remote operation inside the cab.

5. Detachable and adjustable spreader disk mechanism facilitates adjusting the spreading direction and assisting in adjusting the spreading width.

6. The bottom of the whole machine adopts a flat design, and the spreader disk can be folded for direct storage without disassembly when not in operation.

7. The lower part of the storage hopper is an inverted triangular blanking plate, ensuring more uniform blanking of the entire hopper.

8. Screw conveying ensures continuous and uniform delivery of snow melting agents. The adjustable material gate can adjust the delivery volume of snow melting agents according to spreading requirements.

9. The spreader is equipped with a rainproof tarpaulin; the hopper is equipped with an inverted V-shaped device and a top mesh cover; the end of the spreader is equipped with a deflector, etc.

10. Optional pre-wetting function is available, with water tanks installed on both sides of the salt hopper; it can pre-wet snow melting agent particles for rapid melting, enhance the adhesion between particles and the ground to prevent wind blowing and accumulation, and can also be used for spreading snow melting liquid.

Conveying System

It adopts the most advanced chain scraper conveying method in China. Driven by a 3500 torque gearbox, it ensures easy, non-clogging, uniform conveying with stable performance. In particular, it features high operational reliability and low failure rate.

See the conveying system in the figure below:

Hydraulic System

High Safety Performance

The rear non-spreading disk adopts a foldable design for more convenient operation and driving. Spreading dial: straight square cylinder; the height of the dial from the ground is adjustable with different gears, suitable for installation on various vehicle models. Hopper door adjustment devices are installed on both sides of the rear gate, enabling quick cleaning of excess snow melting agent in the hopper when stopping work. Dual strobe arrow lights can effectively remind following vehicles to maintain a safe distance in low-visibility weather conditions. Multiple safety protection devices ensure the safety of operators.

See the foldable spreader disk in the figure below:

The spreader can be folded upward to facilitate quick unloading and automatic stacking of the remaining snow melting agent in the hopper.

Tool List

Binding Strap: 1 pc; Snow Melting Spreader Operation Manual: 1 pc; Engine Manual: 1 pc; Rain Tarpaulin: 1 pc; Certificate of Conformity: 1 pc

Performance Features

1. Wide Application: Capable of spreading coarse salt, fine salt, deicing agents, dry sand, special snow melting agents, etc.

2. High Reliability: Fully hydraulically driven with stable power, stable performance and reliable quality.

3. Strong Corrosion Resistance: The whole machine adopts carbon steel plate or stainless steel structure with three-level anti-corrosion treatment.

4. High Corrosion Resistance of Spreader Disk: The spreader disk is made of high-quality stainless steel with excellent anti-corrosion performance.

5. High Adjustability of Spreader Disk: The height of the spreader disk can be adjusted within 0-500mm; the spreader disk is detachable and reversible for convenient storage when not in operation.

6. High Adjustability of Spreading: The adjustable blanking device (chute) can ensure spreading direction of 45° left, 45° right or straight rear, meeting different spreading direction requirements.

7. Uniform Feeding: The built-in filter screen on the spreader reduces large particles or impurities from entering the equipment, ensuring safe operation of the mechanism.

8. Easy Loading and Unloading: The whole machine adopts a detachable special lifting support system for convenient storage in non-operating state.

9. Customized Protective Cover: The rainproof cover above the hopper ensures normal operation of the whole machine in rainy and snowy days; the rainproof cover is made of imported materials with good flexibility and durability.

10. Stable Material Conveying: The conveying device is equipped with a conveyor belt anti-slip roller device to ensure stable conveying and high efficiency.

11. Rational Structure: The box body adopts a V-shaped hopper with simple structure and easy operation, realizing automatic blanking of snow melting agents with complete discharge and no residue.

Note: Due to continuous product updates, the actual product shall prevail!

简体中文

简体中文